New Raith Electron Beam Lithography (EBL) machine format for shorter exposure times of complicated patterns

Most layout data for EBL in research applications are small and straightforward to handle. To reflect this, the Raith NanoSuite offers an intuitive workflow to design, optimize and immediately (online) expose them without the need to use intermediate machine files.

However, when writing time is crucial, a sequential (offline) pattern preparation workflow is beneficial. In order to take advantage of the higher writing speed offered by Raith VOYAGER, the offline job preparation is now available for VOYAGER. It allows the user to convert the content of a lithography job into a binary file offline before the patterning takes place. The photonics study group around Thomas Krauss of the University of York (UK) found that by switching to the offline preparation, their specific pattern for a large-area photonic nanostructure on thin-film solar cells could be exposed 2.3 times faster, at 7.7h/cm² instead of 17.8h/cm².

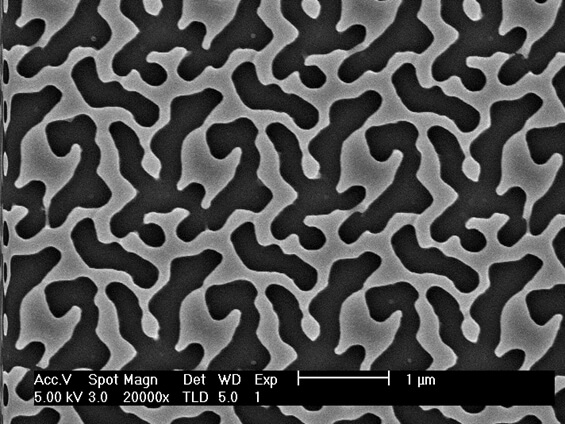

Fig. 1: A light-trapping nanostructure using conventional exposure, step size 28nm. The whole pattern is enlarged up to a few cm² in size.

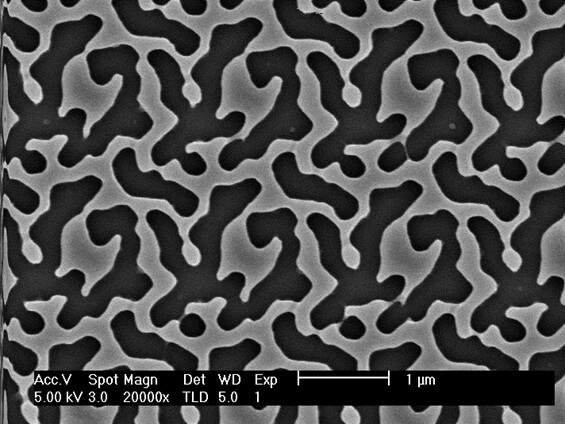

Fig. 2: The same structure written with offline job preparation applied, step size 28nm; no difference in quality can be observed

The greatest impact of this offline data preparation can be achieved in the case of designs with several millions of small, typically repetitive, elements. The user group at York University has expressed their satisfaction over Raith´s cooperation to implement this function. Raith, in return, is very thankful for the constructive support provided by Thomas Krauss´ team in York.

This function is available to VOYAGER users free of charge. If you are interested in upgrading your system, just get in touch with us and we will show you how to enable and use it.