DFB laser devices for fiber optic communication: Prototyping and manufacturing

Fiber optic communication is the only means to satisfy soaring bandwidth demand in telecommunications. New records for fiber transmission data rates are reported every year. All data traveling on fibers stem from semiconductor laser sources, e.g. for:

- sophisticated long haul communication,

- FTTH (fibre to the home) or

- intra-data-centre communication.

Demand for semiconductor laser sources is increasing in step with expanding data volumes.

Semiconductor laser sources are manufactured for specific uses. DWDM (dense wavelength division multiplexed) networks are essential for high transmission capacities. Transmitters in DWDM networks comprise single wavelength emitting lasers with precisely defined emission wavelength. DFB (distributed feedback) lasers, in which the emission wavelength is defined by a grating, have the required emission properties for this purpose.

Questions?

If you have any questions or need more information, just get in touch!

Electron Beam Lithography for DFB laser manufacturing

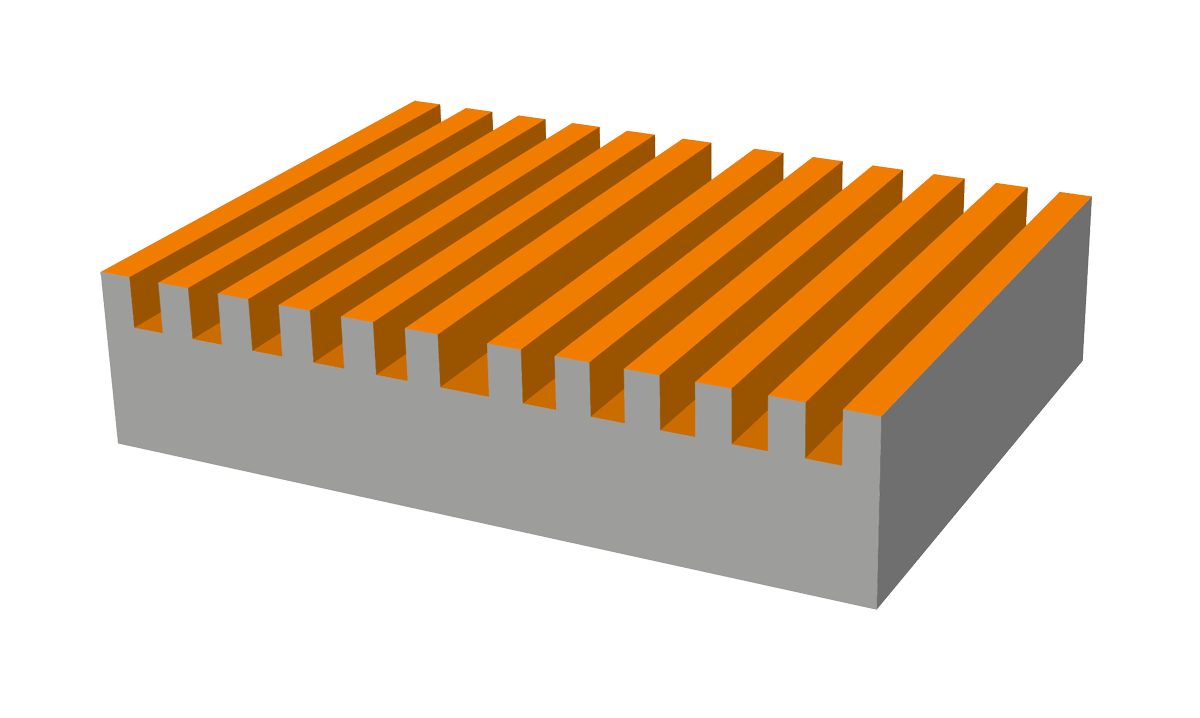

Electron Beam Lithography provides very high writing resolution and high placement fidelity. Given this, it is not surprising that electron beam lithography has been considered a useful method for defining DFB laser gratings from the early days of their manufacturing. However, the details of DFB gratings initially caused some headaches for electron beam lithographers, mainly because of the required pitch definition (the distance between the lines in the grating) rather than the line width (about 100 nm) of the DFB grating structure.

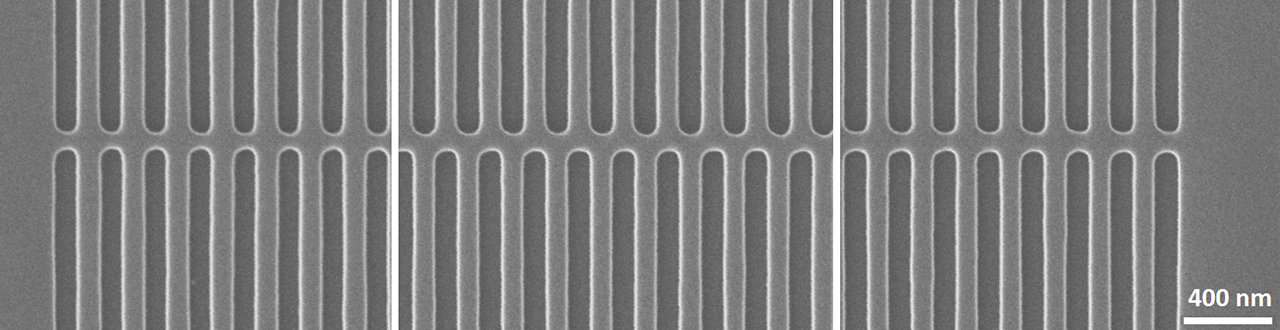

The pitch of the laser grating is about 200 nm for typical materials like InP (and related InGaAsP and InGaAlAs) and depends on the actual target wavelength. The DFB laser pitch needs to be well defined over large areas, as DFB Lasers could be several hundreds of microns in length. A tiny deviation of only 0.1 nm from the target pitch would cause the DFB laser wavelength to change by about 0.7 nm, making a huge difference given the wavelength separation of only 0.8 nm on the 100 GHz DWDM grid for the C band.

DFB laser structure – the challenge

As an alternative, interference lithography with UV light sources could be used to make gratings for DFB lasers. But DFB lasers do not comprise single uniform gratings; in fact, DFB lasers need more complicated grating structures to deliver required emission properties such as:

- true single wavelength emission,

- narrow linewidth of emission,

- good side mode suppression ratio (SMSR),

- high optical power, and

- good modulation capabilities (among others).

In response, DFB laser designers came up with design ideas including

- quarter wave shifts within the grating,

- distributed phase shifts, and

- chirped pitch grating structures.

Interference lithography needs to be constantly adapted to new designs – and for some designs, no solution is possible within interference lithography alone.

DWDM transmitters in use comprise DFB lasers, but also other laser types such as DBR (distributed Bragg reflector) lasers or (widely) tunable lasers with sampled grating structures. The grating schemes of these lasers look quite different to a simple uniform grating.

The best solution for easy and fast DFB laser fabrication

5 reasons why electron Beam Lithography tools by Raith are proven as the best way to tackle the challenges given by DFB (or DBR and tunable) laser makers:

Raith instruments are flexible. A new design idea or a different wavelength (pitch) can immediately be transferred from (CAD) design to production – no need for mask making or setup changes. Same type of wafer in the machine, new design result out. Different designs within a single wafer or within a single photonic integrated chip (PIC) are straightforward to achieve.

Raith instruments provide the means to resolve grating periods with sub-nanometer accuracy. Address resolution down to pm scale has been successfully demonstrated.

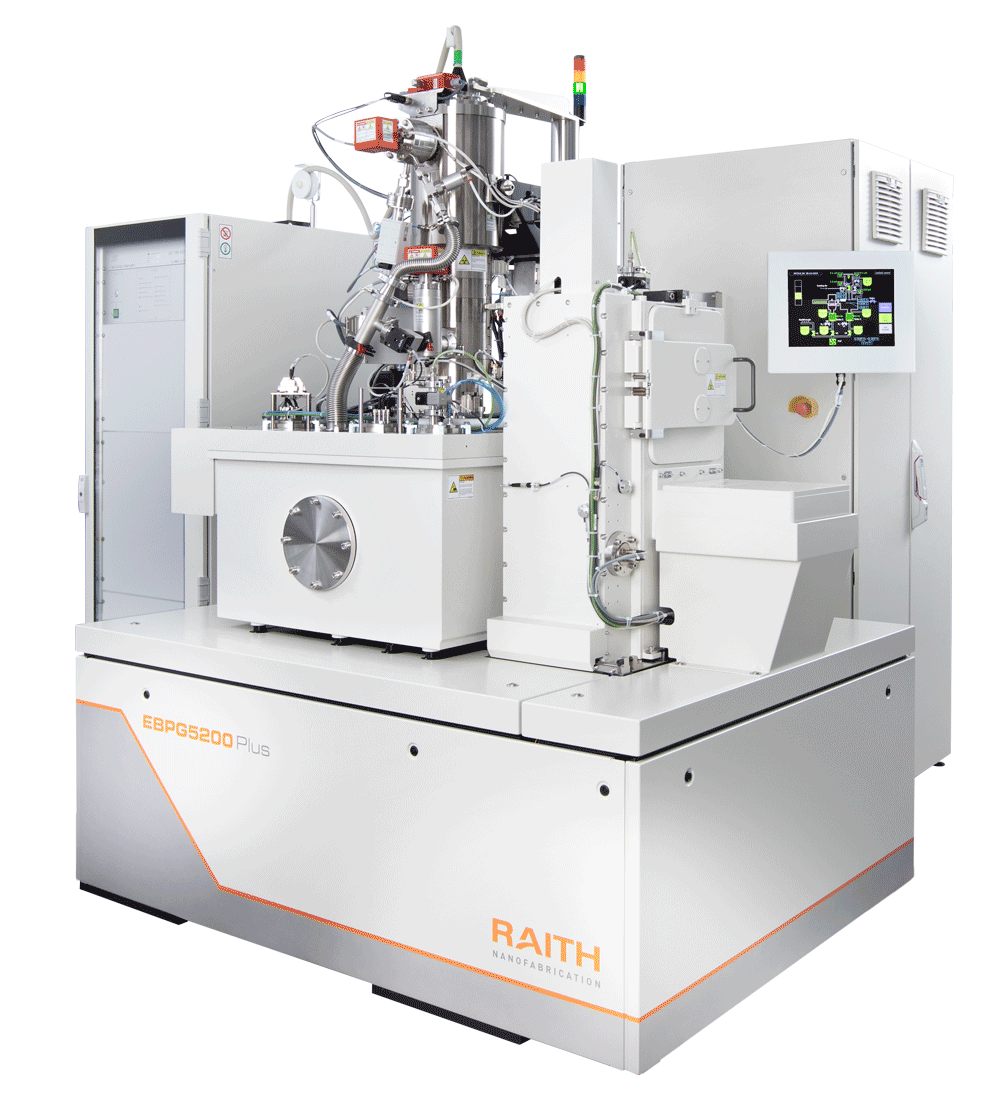

Raith instruments boost yield. Our EBPG tool series eliminates operator interference from wafer loading to unloading. The machine is self-calibrating and all processing is fully automated. This means repeatable and accurate results. Laser manufacturers are particularly dependent on repeatability as deficits in lithography may only become obvious after several (etch and growth) processes.

Raith instruments are fast. High throughput is naturally a production requirement. Writing of about 20’000 laser devices per hour is now a routine job with our machines.

Raith instruments are reliable. As the market leader for Gaussian beam systems we can boast experience from hundreds of Electron Beam Lithography machines installed in the field, many of them operating 24/7 in industrial environments. If assistance is needed, our service and application support centres are close at hand – whether your production is located in the US, Asia, or Europe.

Even if your line of operations is not in production, but focuses on development and prototyping of lasers or other telecom devices, Electron Beam Lithography could be even more useful. We supply a range of machines including instruments which are suitable for academic environments.

If you are not yet familiar with Raith, you are cordially invited to contact us with your production and development needs. We run application labs to provide proof of our capabilities.

Literature

John Carroll, James Whiteaway, & Dick Plumb; Distributed feedback semiconductor lasers, SPIE 1998

Takahiro Numai, Fundamentals of Semiconductor Lasers, Springer, 2nd ed. 2015

Venghaus, Grote; Fibre Optic Communication, Key Devices, Springer, 2nd ed. 2017

Takahiro Numai, Laser diodes and their applications to communications and

information processing, John Wiley & Sons 2010

R. Steingrüber, Z. Zhang; “High performance gratings for DFB lasers fabricated by direct-write e-beam lithography”, Proc. SPIE 10032, 32nd European Mask and Lithography Conference, 100320C (2016/10/20); doi: 10.1117/12.2248862; http://dx.doi.org/10.1117/12.2248862