PIONEER Two´s software scope of delivery expanded:Highest exposure flexibility and full system automation now included in standard configuration - special discount for field upgrade!

State-of-the-art nanofabrication today requires EBL systems with comprehensive patterning strategies and functionality in order to cope with ultimate challenges regarding pattern placement accuracy and fidelity. Catering to this need, PIONEER Two software in standard configuration has recently been enhanced with the addition of major software modules: FLEXposure (also referred to as GDSII patterning attributes), Recipe Manager and Patterning on Image. Further functionalities for handy electron optics parameter and SEM mode control have also been added, as well as a straightforward GUI for scripting and macros.

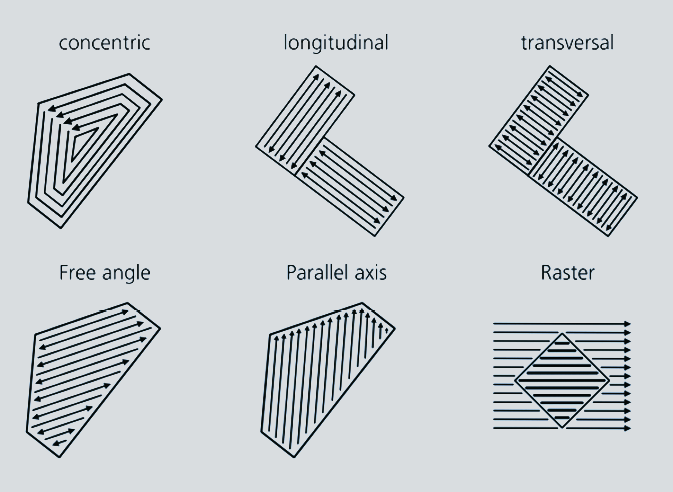

Because nanolithography results can significantly depend on the patterning strategy, maximum flexibility with regard to directional scanning/patterning modes is desired. Fracturing the GDSII shapes in a systematic way with a set of patterning attributes (FLEXposure functionality), e.g. aligning the electron beam movement during exposure to the edges of a GDSII element, can be essential in order to decrease line edge roughness and thus increase pattern fidelity in general.

FLEXposure functionality: Illustration of different patterning modes. Note that all these attributes are assignable for any single individual shape/GDSII element within the GDSII design.

A set of routine patterning parameters and attributes which have typically been established after an elaborate lithography process development can be stored as a recipe in the Recipe Manager software module. For a standard process, this recipe can then simply be dragged and dropped onto further new shapes or groups of shapes in another GDSII design, thus assigning all previously defined patterning info for this standard process at once.

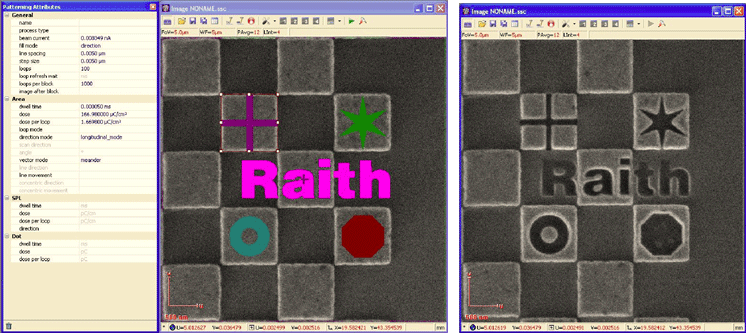

Patterning on image (POI) functionality is convenient, or even essential, for applications using focused electron-beam-induced processing (FEBIP), such as material deposition or sample etching with the help of a gas injection system. POI enables a pattern to be designed directly onto a freshly acquired SEM image and the patterning process started directly with no need for any time-consuming and elaborate alignment procedures at the same sample location. It is important to note that the design is treated as a true GDSII design format within the Raith POI functionality, so that it can be stored, recalled, and modified for subsequent patterning processes

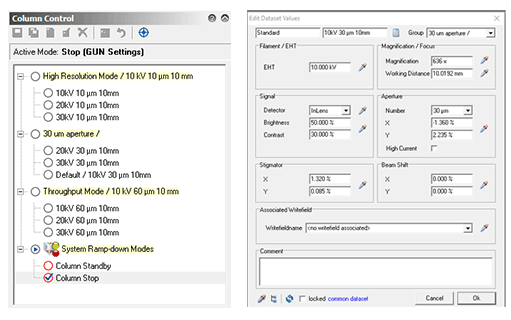

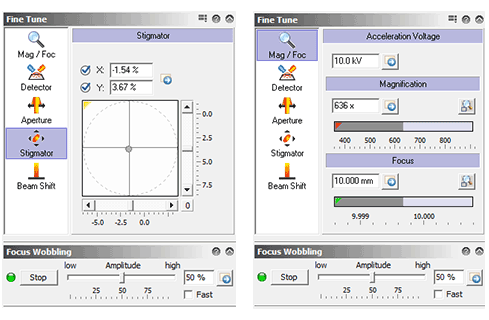

The column control window in the Raith Nanosuite supports convenient SEM mode operation by offering remote parameter control of column settings with sliders. Furthermore, it allows a combination of specific electron column parameter settings to be stored (and recalled) for specific applications or standard processes. These settings can also be implemented in the position list, thus enabling parameters to be changed automatically during an exposure where e.g. switching from high throughput mode to high resolution mode is required.

As mentioned before, all described software functionality will be integral part of the standard software configuration delivered with new PIONEER Two systems, however will also be available for a specially discounted year´s end price as a purchasable upgrade option for existing PIONEER Two systems in the field. Get in touch with us and request a quote for the “Master Users Advanced Exposure Software” package.