The electron beam lithography system for results at the push of a button

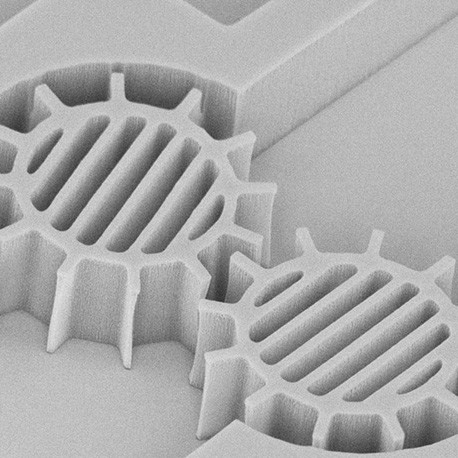

The VOYAGER is a dedicated high-performance electron beam lithography system which is especially suitable wherever straightforward access to electron beam lithography in multi-user facilities is needed. The fully automated and ultra-ergonomic system with smart features and innovative system architecture ensures shortest time to result, making it suitable for both academic and industrial environments.

With features including

- Highly ergonomic human-machine interface ErgoFlow

- Unique formula-based patterning technology algorithmixx

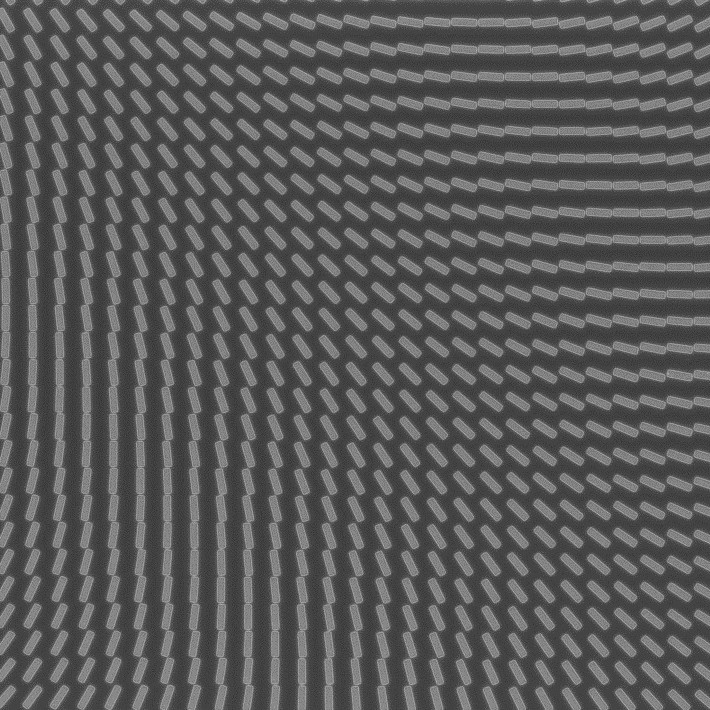

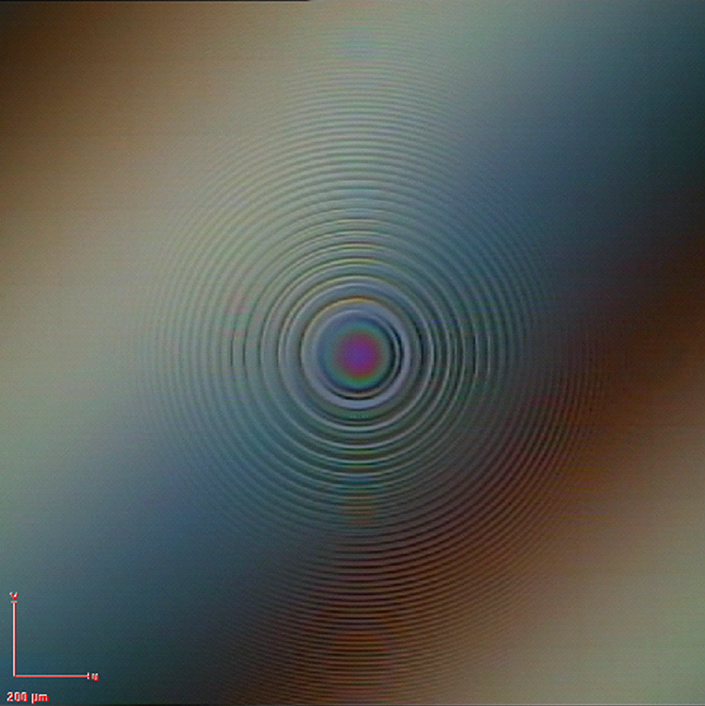

- Flexible directional shape-filling modes FLEXposure

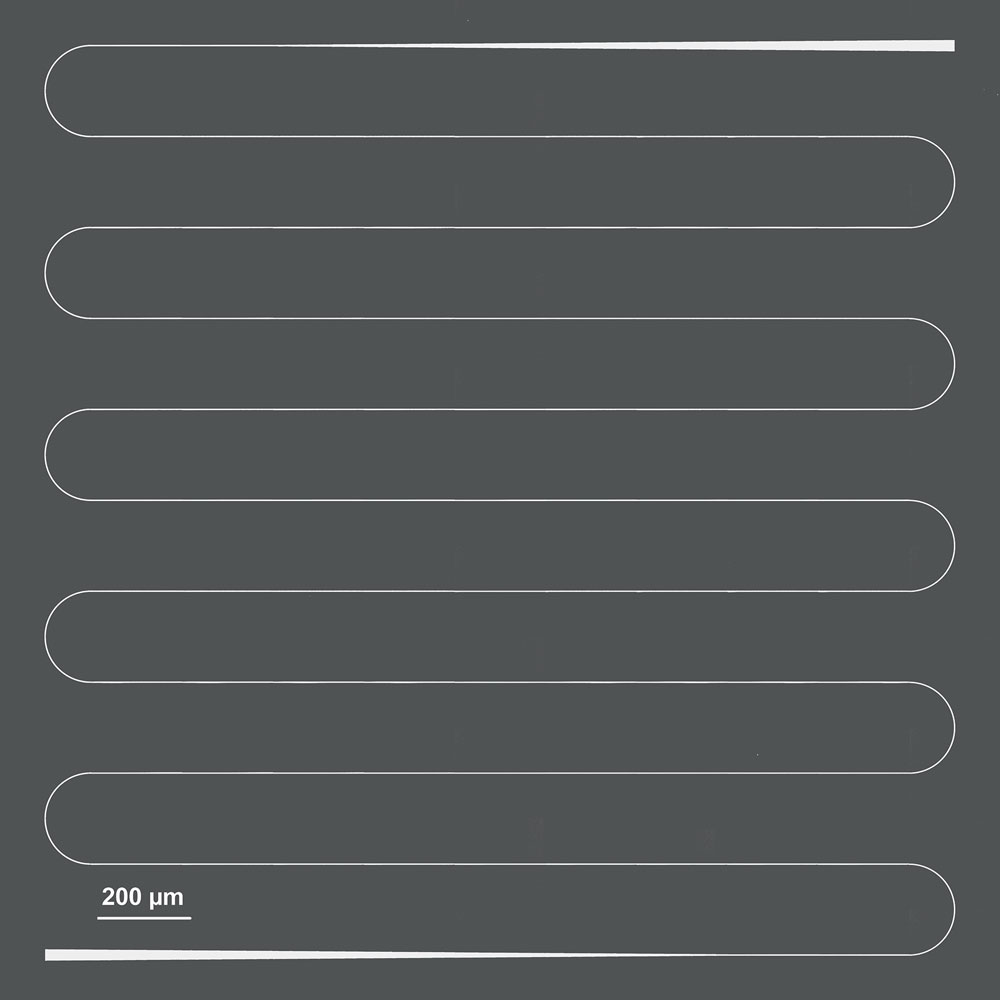

- Stitching-error-free continuous writing modes traxx and periodixx, based on moving stage technology

- 50 kV thermal field emission column technology

- Fully automated write field calibration

- Automatic focus and stigmator setup

- Automatic switch between high-resolution and high-throughput writing modes

Our customers Stanley Lin and Richard Tiberio talk about the VOYAGER at Stanford University

VOYAGER stands for innovation, stable high performance, and ease of use, all at an attractive price/performance ratio throughout the lifetime of the instrument. The VOYAGER electron beam lithography system comes with an environment-tolerant shield which ensures system stability even in less ideal laboratory environments.

Ergonomic interface and automated EBL for shortest time to result

VOYAGER incorporates Raith’s eWrite technology. eWrite combines dedicated EBL electron optics with the latest innovations in pattern generator design that automate system calibrations and batch fabrication. All required corrections throughout the entire exposure job are applied pixel by pixel and “on the fly,” thus saving enormous process time overheads. Depending on the pattern, writing speeds of more than 1 cm²/h can be obtained at highest resolution.

And the degree of automation even goes a step further with the new ergonomic human-machine interface, ErgoFlow. With the help of this smart workflow, professional lithography becomes accessible to everyone – regardless of the level of expertise. ErgoFlow complements the widely used Raith Nanosuite standard software and consists of two elements.

In a first step, any user can easily define an EBL job, which is then parametrized and executed in a second step by a more experienced user. With VOYAGER’s unique sample leveling system, even manual leveling and prealignment are taken care of automatically, thus saving time and drastically increasing your efficiency.

Thanks to its simple usability, ErgoFlow can also leverage interdisciplinary research and sample exchange even between different university faculties or industrial departments.

Features

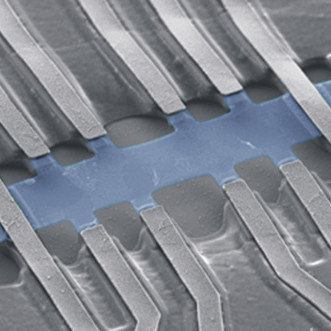

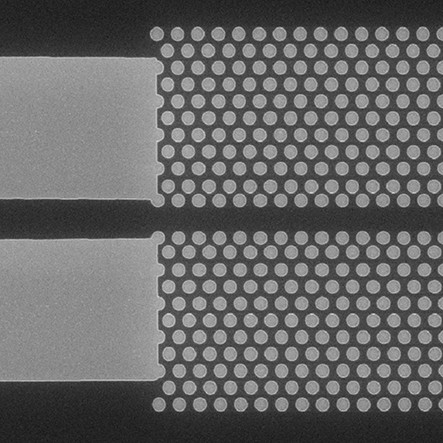

Stitching and overlay

≤ 20 nm

Beam current stability

≤ +/- 0.2 %/h

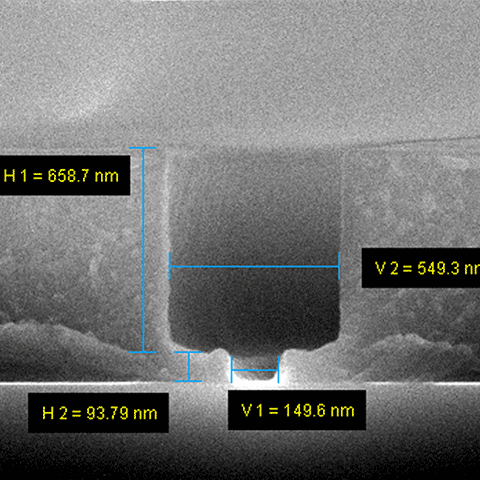

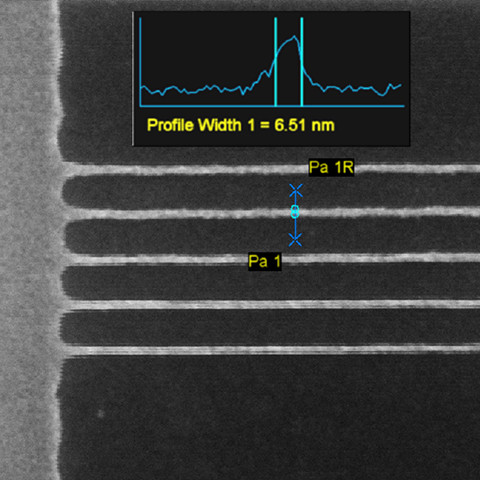

Guaranteed min. linewidth

≤ 8 nm

A high-performance electron beam lithography system with innovative architecture and unique application solutions

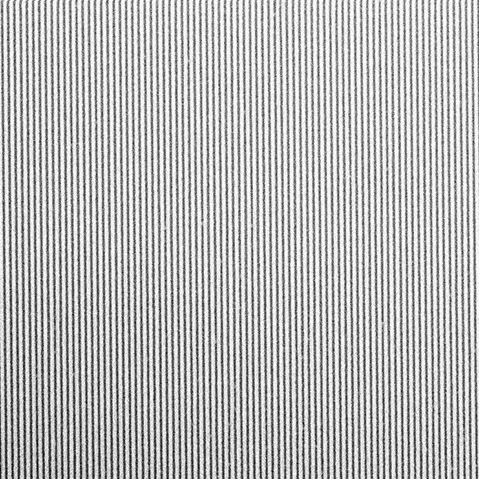

Both hardware and software have been consistently designed for automated exposure operations. Unique software features such as the new formula-based patterning technology algorithmixx and the continuous-moving-stage-based writing modes traxx and periodixx help you to not only increase your efficiency, but also to perfect your device performance.

Applications in the fields of photonics, optics, and optoelectronics benefit particularly from the available software solutions. You can now:

- minimize losses in tapered waveguides,

- tune your grating pitch in the 10pm regime, and

- efficiently handle extremely large design data sets.

Applications

Service

Specifications and system performance parameters are certainly drivers of decision-making where EBL systems are concerned. However, more factors need to be taken into consideration if efficient operation, continous uptime, and subsequent reliable support are to be ensured over the instrument system’s lifetime.

With a worldwide team of professional service engineers, Raith Service ensures you can make the best use of your system. When you decide on a Raith system, all site surveys together with environmental measurements, support with the resulting cleanroom laboratory setup, factory and on-site acceptances, and comprehensive on-site training are always included. Moreover, application support is available free of charge in all global time zones.

Raith service contracts follow a modular scheme and can be configured to match your individual requirements and budget. Visit our Service site or get in touch with us to learn more.

Download VOYAGER brochure

To find out more about the VOYAGER, the possible applications and specifications the VOYAGER product brochure